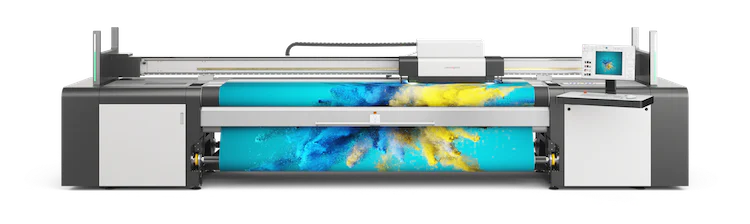

swissQprint Karibu

Karibu is all about efficiency, reliability and a huge variety of roll printing applications.

Width

Productivity

Resolution

This large format printer incorporates the result of 20 years’ development experience in UV inkjet printing, made better still by innovative technical solutions.

Karibu users have a clear competitive edge …

- Get to your print more efficiently with unique roll to roll printer features powered by new output software.

- Get to your print more reliably based on the decades of experience that have gone into Karibu and its 100% Swiss pedigree.

- Get to print more applications thanks to cool LED technology and a specially developed ink set.

Neon

Attention grabbers: neon yellow and neon pink give printed materials that sensational look.

Varnish Effects

Karibu can enhance roll media by means of effect varnish. Be it applied partially, as an overall cover.

Customise your printer. We’ll make it just for you.

Double-sided printing option

Automatic double-sided production. Done in no time! You can count on it.

Dual roll option

Karibu doubles productivity with parallel processing of two rolls up to 1.6 m wide.

Colours

9 colour channels are available. How would you like to configure them?

Extras elsewhere, but standard from swissQprint.

Cassette system

A powerful vacuum holds substrates flat and firmly in place.

Tip Switch Vacuum

Karibu features a controlled and finely segmented vacuum system with fingertip adjustment.

Light Box

Karibu users can monitor backlit prints practically in real time using the Light Box function.

Mesh Kit

Karibu does mesh and full bleed printing with no need for liner. And with no clean-up afterwards.

X-Control

Karibu’s beam is movable between two defined positions: standard and mesh.

Multilayer printing

Mirrored, identical or different, Karibu prints multilayers onto transparent media with accurate registration.

Profitable LED technology

LED curing is cool. This means heat-sensitive media can join the portfolio and open up lucrative markets.

Certified energy efficiency

swissQprint LED systems are all proven to be highly energy efficient (ISO 20690:2018).

Key figures and model comparisons at a glance.

Productivity

| Top Speed | 212 m²/h |

| Production |

110 m²/h

|

| Quality |

75 m²/h

|

|

Fine Art

|

17 m²/h

|

Dimensions

| Print Area | 3400 mm |

|

Material thickness

|

maximum 3 mm

|

|

Roll width

|

maximum 3400 mm / dual roll 2 × 1626 mm

|

|

Roll weight

|

maximum 200 kg / dual roll 180 kg each

|

|

Roll diameter

|

maximum 380 mm

pneumatic roll holder for 3″ core diameter |

Equipment/Options

| Curing |

UV LED

|

|

Double-sided printing

|

Option

|

|

Dual roll option

|

2 × 1626 mm

|

|

Casette system

|

Standard

|

|

Light Box

|

Standard

|

|

Mesh Kit

|

Standard

|

|

Tip Switch Vacuum

|

Standard

|

Colours

|

Colour channels

|

maximum 9

|

|

Print heads

|

maximum 18

|

|

Print heads per channel

|

1 or 2

|

|

Light cyan, light magenta, light black

|

Yes

|

|

White

|

Yes

|

|

Varnish

|

Yes

|

|

Orange

|

Yes

|

|

Neon

|

Yes

|