Invented roughly 40 years ago, dye sublimation is a unique printing process where dye transitions between a solid and gas state to transfer onto a substrate. This revolutionary printing technique involves printing a mirrored dye image on paper. The dyed paper is then layered on top of polyester fabric and passed through a heating press at 195 degrees Celsius. This extreme heat creates a reaction that allows the colour to penetrate the fabric permanently.

Today, dye sublimation is a highly regarded printing technique that delivers vibrant, long-lasting designs, prominently seen in custom apparel, promotional products, and professional photo printing. Its adaptability is evident across a spectrum of industries, encompassing fashion, home decor, signage, ceramics and sports equipment.

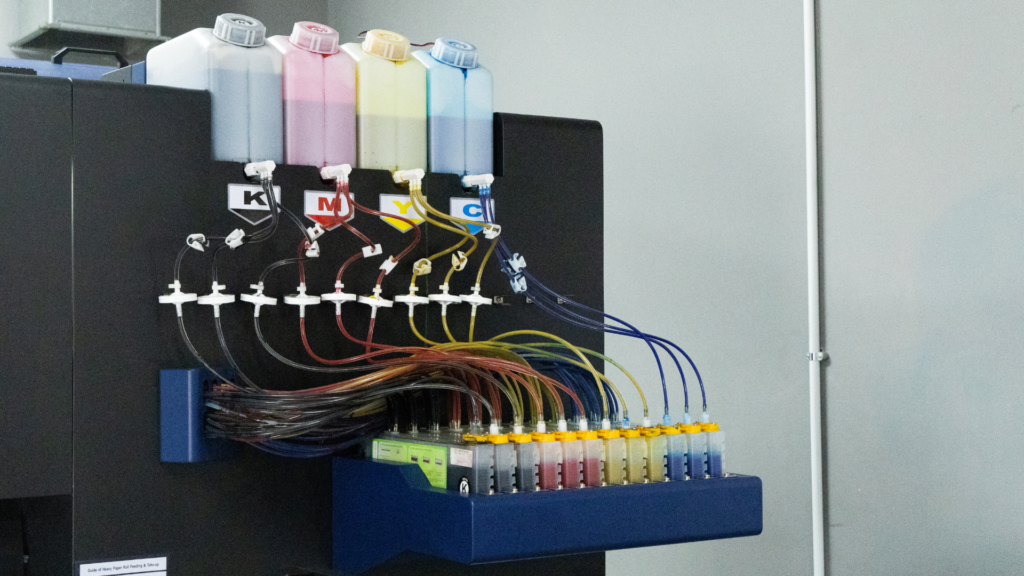

Quality inks are essential for high-quality prints. The variety of inks in the industry is vast, making the choice a challenging one. Aqueous dyes are water-based, positioning them as eco-friendly and ideal for indoor applications. In contrast, solvent dyes, which are oil-based, offer more durability, making them suitable for outdoor applications due to their resistance to environmental factors. However, for dye sublimation inks, aqueous dyes are the preferred choice. Yet, not all aqueous sublimation dyes are created equal. Many inks on the market have limitations. A significant challenge is the restricted colour palette, as creating standard CMYK colour ink sets with traditional formulas remains a hurdle.

With over 44 years of experience in large-format printing and working with colour management experts at ColorFlow Solutions, we’ve listened to customer feedback and identified a need for improved dye sublimation ink. Our association with Monti Antonio, leaders in the technology and manufacture of the heat transfer press, has also supported us in developing the perfect ink formula. The E-series inks are truly game-changing, offering better colour, more cost-effective production, and enhanced outdoor durability.

Technically speaking, the E-series inks shine with their unique chemical formula, providing a broader colour gamut and exceptional outdoor durability. This results in more vibrant colours, smoother colour gradients, and faster drying times. A notable feature is their compatibility with lighter, more affordable paper, even as thin as 25gsm. Such thin paper speeds up the heating process, leading to quicker sublimation and significant cost savings. Additionally, these inks are designed to be printer-friendly, versatile for various textiles, and produce bright colours with clear images, sharpness, and deep blacks.

One of our major clients, National Flag, transitioned to E-Series inks and couldn’t be happier. In fact, a long list of satisfied clients can attest to the benefits of this superior ink formula. While every product might face some criticism, the E-Series inks have received none so far, highlighting their quality, performance, and customer satisfaction.

Looking to the future, we are constantly developing the E-series inks to enhance the colour spectrum, with a special emphasis on perfecting black.

In conclusion, the E-Series Sublimation Inks by SIGN-TRONIC are a groundbreaking addition to the printing industry. They strike the right balance between technical and practical advantages, making them an obvious choice for our clients. For those in the dye sublimation industry, these inks are a must-try.

Recent Comments